University of Glasgow research will help astronauts breathe on moon

Published: 10 October 2019

A University of Glasgow researcher has successfully extracted oxygen from moonrock – an exciting discovery which will help astronauts breathe on future human missions to the moon.

A University of Glasgow researcher has successfully extracted oxygen from moonrock – an exciting discovery which will help astronauts breathe on future human missions to the moon.

The work of PhD student Beth Lomax, which could also help propel rockets with oxygen, has been supported through the European Space Agency’s Networking and Partnering Initiative, harnessing advanced academic research for space applications.

Beth has based her work on the FCC process – from the initials of its Cambridge-based inventors – which has since been scaled up by a UK company called Metalysis for commercial metal and alloy production.

Mark Symes, Beth’s PhD supervisor at the University of Glasgow, said: “We are working with Metalysis and ESA to translate this industrial process to the lunar context, and the results so far are very promising.”

Samples returned from the lunar surface confirm that lunar regolith is made up of 40-45% percent oxygen by weight, its single most abundant element.

“This oxygen is an extremely valuable resource, but it is chemically bound in the material as oxides in the form of minerals or glass, and is therefore unavailable for immediate use,” explains Beth.

This process would give lunar settlers access to oxygen for fuel and life support, as well as a wide range of metal alloys for in-situ manufacturing – the exact feedstock available would depend on where on the Moon they land.

“It could also be used to extract useful materials on Mars as well, where pre-processing the feedstock would give pure metals and alloy products,” adds ESA materials engineer Advenit Makaya.

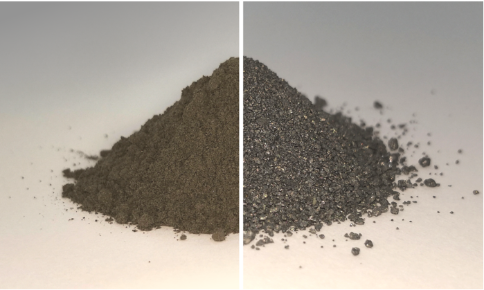

On the left side of this before and after image is a pile of simulated lunar soil, or regolith; on the right is the same pile after essentially all the oxygen has been extracted from it, leaving a mixture of metal alloys. Both the oxygen and metal could be used in future by settlers on the Moon.

First published: 10 October 2019

<< News